Check out some custom equipment and fabrication I have done:

I am proud to have fabricated a wide variety of glass equipment and provided additional services for the following studios: Bowling Green State University, Mikula Glass Studio, Owens Community College, Southern Illinois University Carbondale, Third Degree Glass Factory, the Toledo Museum of Art, and Tulsa Glassblowing School.

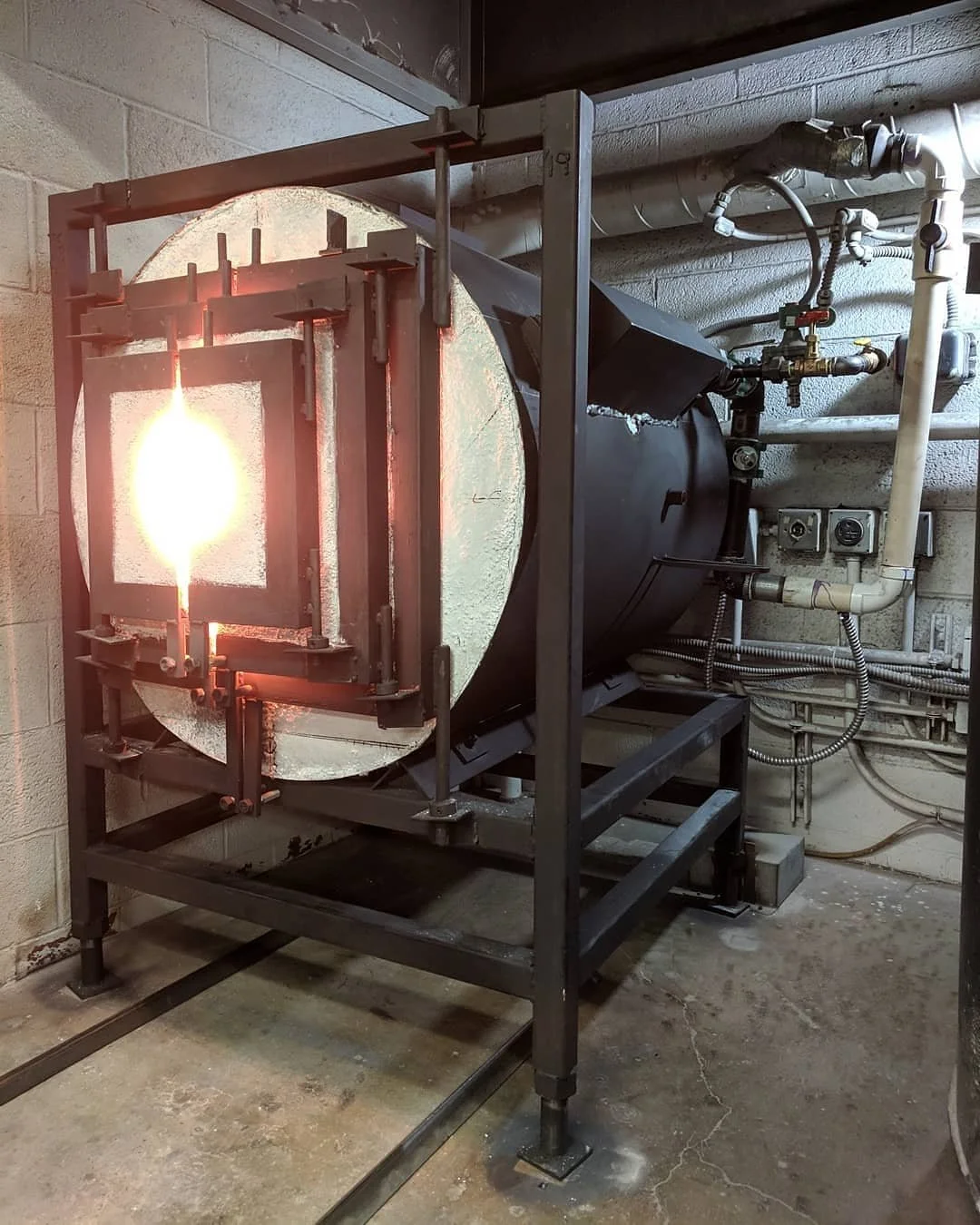

Gloryhole: Designed and fabricated brick reheating chamber: 20” retention ring opening, 24” interior diameter, 33” depth. 2019.

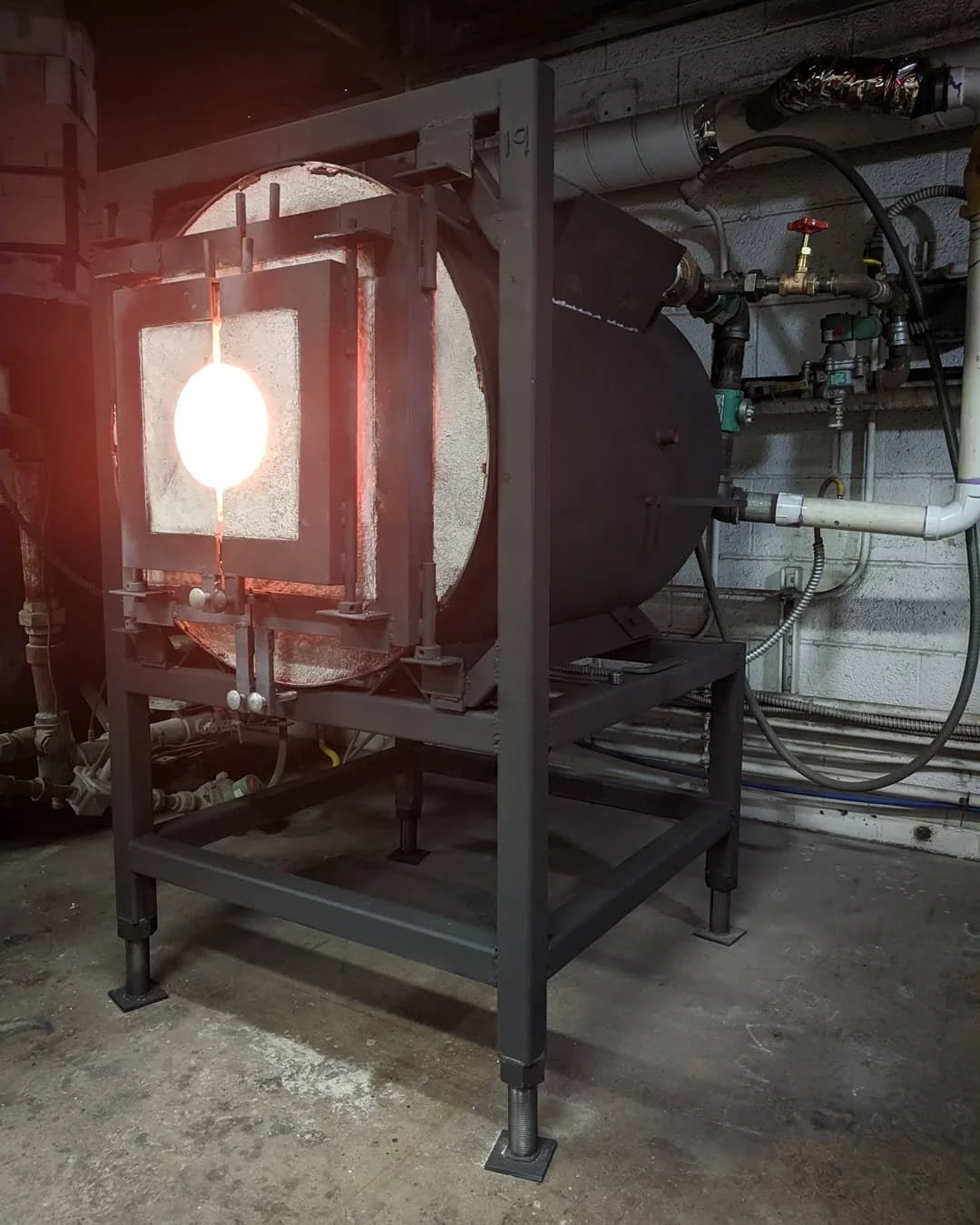

Gloryhole: Designed and fabricated brick reheating chamber with ribbon burner: 13” retention ring opening, 16” interior diameter, 24.5” depth. 2019.

Pipe Turner: Designed and fabricated automated pipe turner and garage. 2020.

Garage: Designed and fabricated new garage with movable doors and attached pipe warmer with ribbon burner. 2021.

Garage: Designed and fabricated new garage with movable doors. 2025

Ventilation Hood: Designed and fabricated ventilation hood and insulating panels for new hotshop. Also installed and plumbed all equipment. 2020.

Heat Shields: Designed and fabricated new heat shields with CNC plasma cut color scoop holders and shade 5 viewing ports. 2023.

Hotshop Benches 2024

Reverse side of hotshop bench 2024.

Hotshop Benches: Designed and fabricated two hotshop benches with wood on left rail. 2025

Wheelchair Bench: Designed and fabricated adjustable wheelchair accessible hotshop bench for public programming. 2025

Lathe Stand: Designed and fabricated new lathe stand/motor mount for Spatzier lathe. Complete with emergency stop and variable speed drive to meet university safety standards. 2022

Fabrication Work: In 2022 I was contracted to fabricate 28 of these 14-foot steel arches in accordance with engineer specifications to support this permanent public glass installation at Owens Community College in Toledo, OH